The Transformative Power of 3D Printing

My name is Chris Griffin, and I have been running my private solo general dental practice since 1999. After a fire destroyed my practice, I was compelled to change several practice systems, leading me to advocate for the transformative power of practice automations, particularly 3D printing, in revolutionizing dental workflows. Teaching fellow dentists how they can leverage 3D printing to deliver exceptional clinical outcomes while significantly reducing overhead costs has become my true passion and driving force. Additionally, I take immense pride in my charitable work through organizations like Mission of Mercy and Dentistry with a Heart.

The decision to incorporate 3D printing in denture production stemmed from two significant factors. Firstly, we observed a decline in the quality of work provided by our dental lab since the onset of the pandemic. Alongside this decline, there were price increases, missed deadlines, and growing lag time between submitting a case to the lab and receiving the next step. Witnessing patients with insurance coverage for extractions through state or federal insurance unable to afford dentures and restore their smiles was disheartening. Even with modestly priced denture lab services, many patients could not cover the associated costs.

Ultimately, my primary motivation for embracing 3D printing in denture production was to gain greater control over all aspects of the denture lab process and overcome the excuses that hindered progress. My initial venture into 3D printed dentures dates back to 2014 when I was already disillusioned with the quality of my denture lab. Despite the lack of FDA-approved denture materials at that time, we found a way to expedite the process of duplicating existing dentures. For instance, if a patient presented with a broken denture and required a replacement quickly, we would glue their broken denture together, scan it using our Planmeca CBCT, convert the resulting DICOM file into a .stl file compatible with our 3D printer software, and create an exact duplicate using tray resin through a four-hour printing job. We usually printed these overnight due to the time involved. The following day, we used the duplicate denture as a custom impression tray to take a VPS wash impression inside it. Combined with a bite, we sent this to the denture lab, bypassing one step in the denture process.

Although this approach was laborious and not highly cost-effective, it offered a glimpse into the possibilities of the future. In fact, in 2015, I delivered what I believe was the first-ever lecture on 3D printed dentures in Nashville, Tennessee, titled “True 3D Dentistry,” outlining this specific procedure. Unfortunately, very few, if any, of the attendees were inspired enough to begin 3D printing in their practices at that time.

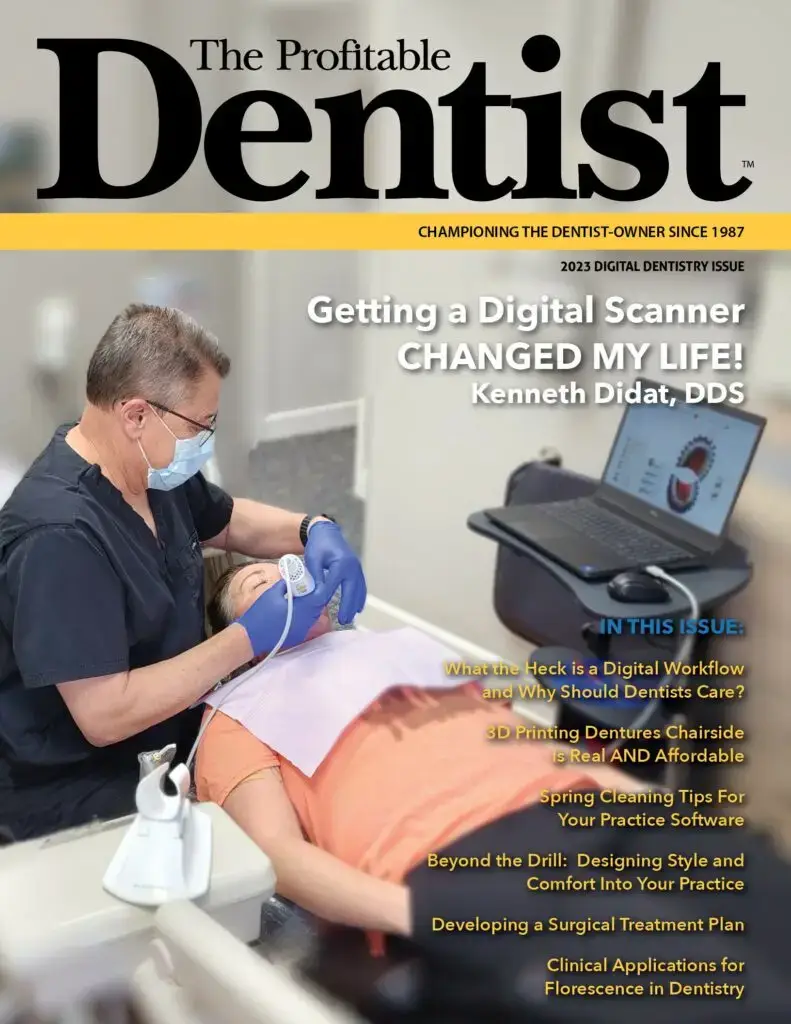

Fast forward to 2020, when the FDA began approving 3D printing resins suitable for fabricating dentures. That year, I purchased a faster 3D printer at half the cost of my 2014 model and a digital scanner capable of capturing both hard and soft tissue to generate the necessary .stl files for denture design. We have now expanded our 3D printing capabilities to include various dental applications such as crowns, surgical guides, nightguards, and models.

As is typical with any change in practice protocols, my staff initially expressed resistance, but we gradually overcame their objections through a strategic approach to implementing 3D systems, including team delegation. This ultimately resulted in increased productivity and performance from every staff member, alleviating pressure on me, the dentist. During the first six months following the printer’s purchase in 2020, my staff allowed me to handle all the designing and 3D printing in the practice. Towards the end of the year, I expressed my desire for them to assume the bulk of these responsibilities. We conducted in-service trainings, watched webinars and YouTube videos, and developed streamlined workflows and systems for them to follow. However, when faced with challenging scans or confusion, they would occasionally revert to using traditional PVS impression material or alginate and stone. As a busy dentist, there were days when I attempted to enforce compliance, but there were also days when I lacked the energy to insist on adherence to our new protocols. It took a drastic measure to fully transition my practice to a digital workflow. Over the Christmas break in 2020, I removed the stone grinder from our stone lab and disposed of a box of perfectly usable dental stone. I also locked all alginate and PVS materials in my private office, leaving no fallback options. Although there was initial resistance and complaints for two weeks in January, we haven’t looked back since. Now, my staff can’t imagine a time when they opposed having a digital practice. The digital scanners and printers have become indispensable to them. We even repurposed our old stone lab into a 3D printing lab, where one of our chairside assistants dedicates her time to designing and printing various dental items. Due to the efficiencies gained, there was no need to replace her chairside, and the practice now operates more smoothly with her handling most of our in-house lab work.

Becoming proficient in 3D printed dentures has been an intriguing journey in my practice, and I now feel confident delivering them to my patients. However, it is worth noting that materials are constantly evolving and improving, which means this advice may become outdated soon. The most significant challenge in adopting 3D printed dentures lies in the process of transforming patient records into software capable of generating 3D objects printable by the 3D printer. Various software options are available on the market, with the two largest providers offering different business models. The more robust software is relatively expensive, both upfront and in terms of ongoing fees. On the other hand, the second option, while slightly slower in design, incurs a $25 fee each time a design file is exported for printing. To encourage more dentists to embrace this incredible technology, I advocate for teaching courses using free or low-cost software.

When I designed, printed, and polished my first denture, it took an arduous 14 hours. This lengthy process was due to several factors, including a lack of education, unfamiliarity with the design software, and substantial trial and error. Today, we can scan, design, print, and process a denture that far exceeds the quality of that initial one in approximately one hour. In fact, during the recent Mission of Mercy event in Memphis, Tennessee, I wanted to test the number of dentures we could produce within a short timeframe. Equipped with two 3D printers, all necessary accessories, and two team members, we were able to scan, design, and deliver 33 partial dentures to patients within 12 hours. That amounts to roughly three dentures per hour, highlighting the potential when focused on denture production alone.

I envision a future where chairside 3D printed dentures will be at the same stage of development as milled Cad/Cam crowns were a decade ago. While I haven’t recently reviewed denture lab costs, about a year ago, we calculated that designing and printing a denture cost us $41 per arch, compared to the $383 per arch we paid to our denture lab. Although resin costs have not risen significantly yet, denture lab expenses may have increased during that time frame.

The most surprising outcome of incorporating 3D printing into my practice was the overall positive impact it had. By printing other items such as clear aligner models in-house, we reduced lab fees and were able to offer lower fees for clear aligner cases. This led to a tenfold increase in the number of clear aligner cases we handled in the past two years, capturing a significant portion of the market. Additionally, the ability to design and print our own implant surgical guides reduced both costs and wait times, ultimately resulting in more patients opting for implant treatment. We also discovered that we could create high-quality nightguards and splints for less than $10 each, further reducing prices and increasing the number of cases we completed. Furthermore, when we began 3D printing aesthetic mockups for patients, allowing them to visualize their new smile design rather than relying solely on photos, the number of patients opting for extensive cosmetic work multiplied. These achievements empowered me to gradually sever ties with the worst PPO insurance plans. In the past two years, we transitioned from participating in over 20 PPOs to currently only participating in three. As a result, both 2021 and 2022 marked the best years in the history of my practice, and the first quarter of 2023 saw a 20% increase over 2022. If someone had told me in 2019 that embracing 3D printing would enable me to become more independent from insurance companies while experiencing the best years of my dental career, all while practicing only three days per week, I would have never believed it possible.

There are numerous paths to practicing exceptional dentistry, and I don’t claim to know the best approach for everyone. However, it is crucial to consider the external factors that will make maintaining the status quo of outsourcing all lab work increasingly difficult, both financially and logistically. Any amount of dental lab work that can be brought in-house is an asset to your practice. The more procedures you become proficient in, the better. You don’t have to master everything at once; you can start with the basics and gradually incorporate more complex procedures over time.

As an independent solo general dentist, I find immense satisfaction in producing my own dentistry under my own roof, where I can take pride in the results. This is the future I envision for all of us.